My college professor would always say in class; you don’t know, what you don’t know. At the time, as a college student, that saying was completely lost on me. Fast forward to today, I have seen the wisdom of that idiom play out time and time again with the businesses and warehouse operations we have helped.

I find myself repeating my professor in many business meetings: “You don’t know, what you don’t know.”

The power of information, especially business intelligence in these digital days cannot be understated. Being able to access weekly, daily, and up to the minute data has a dramatic impact on warehouse operations. In fact, having conversations with customers before and after integrating our WMS they’d remark that it was like night and day, the difference in their operations and how they approached it.

Below are my top 5 places of impact in a warehouse

- Labor Productivity – Real time data can measure labor productivity in receiving, picking, and shipping. Measuring and employee’s number of picks, putaways, accuracy and average times throughout the week and during their shift can lead to key insights. Who are your key performers? Who might need more training? Are there any on-floor habits that need to be addressed? This can reveal training needs, employee assignments that take advantage of their talents or needed action.

- Reporting – in the past reporting could be a real task. Taking multiple reports or spreadsheets and combining them into one document or PowerPoint can take hours if not days to produce. Then by the time you send or present the report, the data has already changed.

With Real-Time Data the WMS can provide general and customized reports that can be automated to run and then emailed or even texted to managers and executives so they can see how the warehouse is performing. Another key element to this is the data can be presented in a data or visual form with graphs.

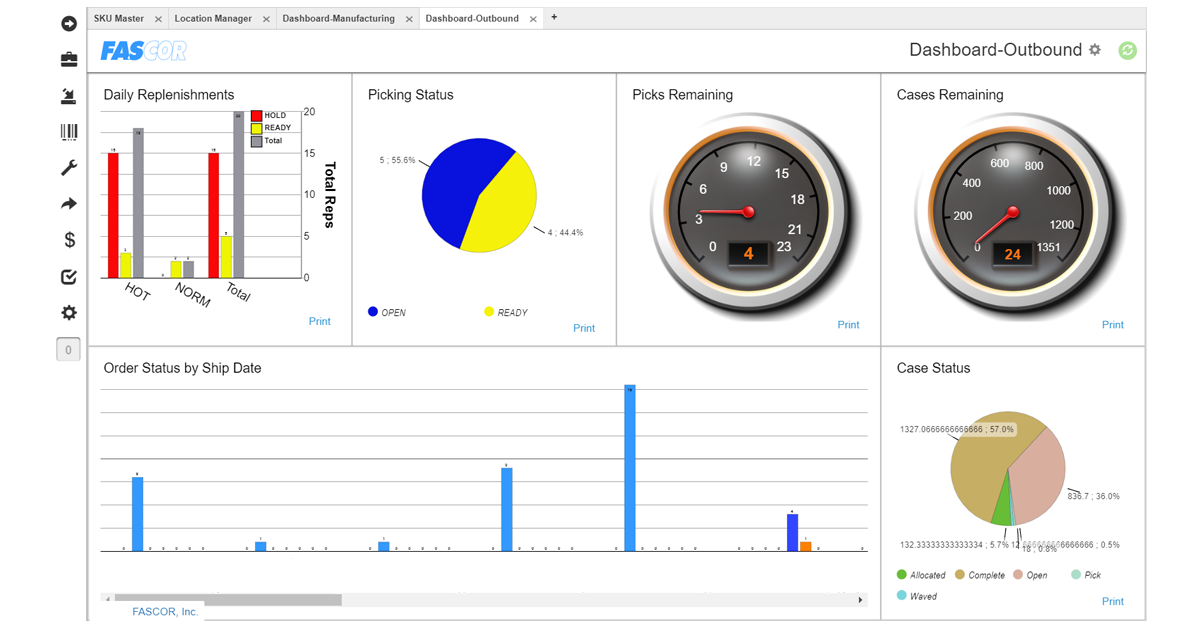

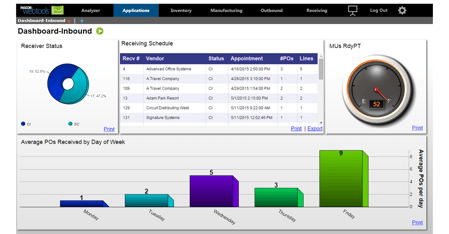

- Dashboards – Over the past few years, if you have walked through any major distribution center you will see large monitors that display an array of dashboards for the warehouse team to see. On these dashboards they could see the progress of receiving inventory or how many picks are left in the shift. These dashboards are used to keep the warehouse staff up to date on their workday and progress.

- Warehouse Space Efficiency – With real time data – You can analyze where your slow-moving inventory is being stored and adversely where your high turn products are located. By analyzing and then moving these products to align with picking, you can reduce time to pick as well as reduce total steps taken.

- Get to Decisions Faster – Armed with the most up-to-date business intelligence, teams can make data-driven decisions and be confident that they are doing what is best for their operations and staff.

While many see real-time data as a perk to integrating a WMS, it quickly becomes the one tool they can’t live without.

Want to learn more about the FASCOR business intelligence and real time data? Click here