It’s no secret that managing e-commerce and omnichannel order fulfillment operations have become increasingly difficult over the past year. As the events of 2020 have unfolded, supply chains strain to keep up with not only the demand for products but to ship them in a timely manner to keep customer confidence and loyalty. Many companies have started to examine their warehouse operations for cost saving opportunities as well as quick ways to improve efficiencies and productivity.

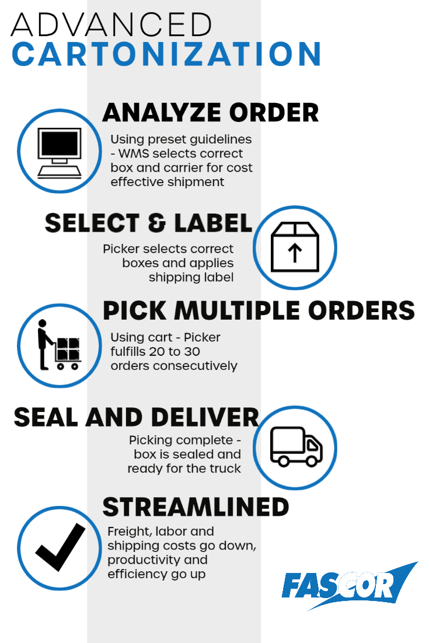

Advanced Cartonization

There a lot of innovative (and expensive) solutions out there that can help get the job done. However, as my Father would say, sometimes the easy solution is the best solution. That leads us to what we call Advanced Cartonization or Pick to Box.

Imagine a warehouse, pickers are on the floor going from location to location picking one or two orders into totes. When complete they walk to a pack station and drop off the materials to be packed and ship. Rinse and repeat. This strategy requires a lot of labor and can lead to unacceptable error rates. There is also a good chance the company is losing money in shipping by not taking advantage of the new DIM weight protocols.

Using pick to box in a warehouse can take the guess work out of the DIM weight rules before a single item is picked. Using the FASCOR WMS software, the system analyzes the size, weight and dimension of items to be picked and directs the picker to the appropriate box to select. It also rate shops the shipping companies to get the best rate, while still meeting customer expectations. The system prints out the shipping label to be placed on the box, again, all before a single pick. The picker then fulfills all the orders with a mobile picking cart with the pre-labeled boxes on it, now picking 20 to 30 orders in the same time it took to pick one or two.

The method also effectively eliminates the need for packing stations as well as significantly decreases shipping costs and error rates. One of our clients, saw an almost 500K saving each year in freight and labor costs.

Advantages to Pick to Box

- System directed box selection (DIM)

- 100% vendor and carrier compliant labeling

- Reduced shipping costs

- Reduced labor needs

- Elimination of packing stations

- Reduced error rates

- Maximize orders per truckload

Want to know more? Click here for an informational data sheet on Advanced Cartonization or click below to schedule a 30 minute demo.